Proper Lighting Evaluation for Industrial Facilities

Discover the Best Practices for Industrial Lighting Evaluation

Whether you prefer a DIY lighting assessment or want the experts at Tactik Lighting to handle it for you, understanding your facility's current lighting and how to improve it is essential for productivity, safety, and energy efficiency.

With proper lighting evaluation, you’re not just replacing fixtures — you’re making smarter decisions that impact operational efficiency, worker safety, and compliance with national standards.

Why Lighting Evaluation Matters

Lighting is often overlooked when assessing facility performance, yet it's one of the most cost-effective areas to optimize. Poor lighting leads to:

- Inconsistent product quality in visual-based processes

- Visual fatigue and reduced employee performance

- Safety risks due to inconsistent illumination

- Increased energy consumption

A comprehensive lighting evaluation ensures you're not leaving performance — or savings — on the table.

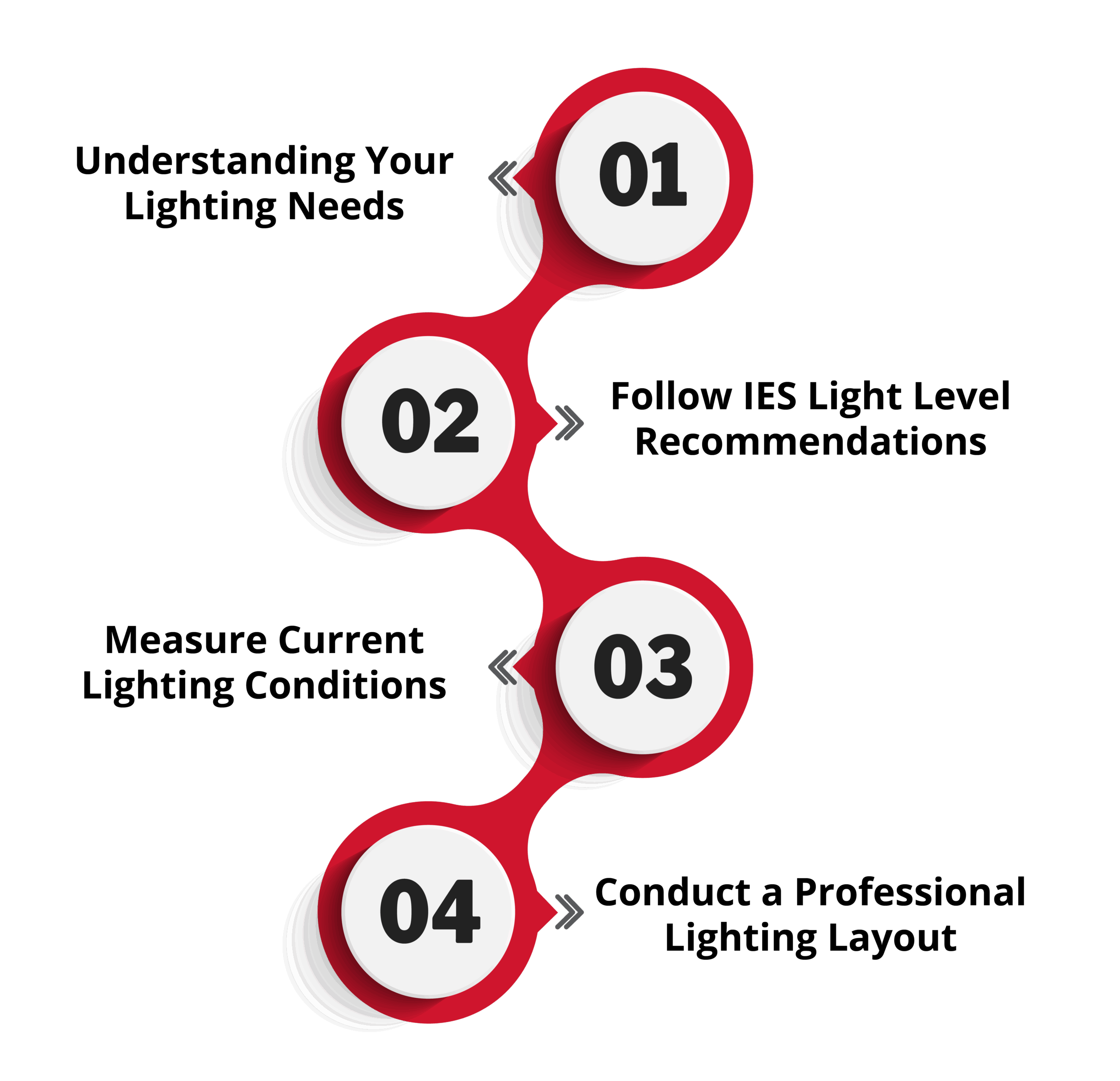

Step-by-Step Evaluation Process

Experience has taught us that a systematic approach is required for success. We drive consistency and sweat the details so you never end up with an LED lighting solution that’s less than ideal for your facility.

1. Understanding Your Lighting Needs

Every facility is unique. Our evaluation begins by:

- Reviewing operational goals

- Identifying critical work zones

- Understanding employee tasks and safety regulations

- Considering shift patterns and maintenance constraints

We tailor recommendations to your actual workflows — not just a generic standard.

3. Measure Current Lighting Conditions

A precise measurement strategy is key to effective evaluation:

3a. Foot Candle Readings:

- Use calibrated foot-candle meters to capture both vertical and horizontal illuminance

- Ensure a uniformity ratio of no more than 3:1, minimizing shadows and visual strain

3b. Reflectance Assessment:

- Measure the reflectance values of ceilings, walls, and floors to understand how surfaces distribute light

- Identify low-reflectance zones that may require supplemental lighting

3c. Air Quality Observations:

- Assess the presence of suspended particulates that can obscure fixtures or reflectors, especially in foundries, papermills, tissue mills, steel mills, aluminum diecasters

- Recommend fixture enclosures or lens types accordingly

3d. Temperature Logging:

- Deploy temperature loggers at fixture height and outside the facility

- Record data for at least 2 weeks to analyze thermal conditions as choosing an LED fixture that doesn’t meet the design specification will assure premature failure as LED drivers do not like heat.

- Compare internal vs. external air temperatures to account for seasonal changes that may impact lighting performance or longevity

2. Follow IES Light Level Recommendations

The Illuminating Engineering Society (IES) sets recognized standards for light levels in various industrial settings. We ensure your facility’s lighting:

- Meets or exceeds IES recommendations for each area

- Supports safety inspections and visual tasks

- Promotes compliance with OSHA and local building codes

4. Conduct a Professional Lighting Layout

Once current conditions are benchmarked, we run simulations to find the ideal lighting design:

- Use lighting design software (e.g., AGi32 or Dialux)

- Test different fixture types, distributions, and mounting heights

- Present layout options tailored to your needs and IES standards

We also evaluate:

- Energy consumption by fixture type

- Potential maintenance and labor savings

- Long-term ROI and rebate eligibility

Tactik Lighting:

Your Evaluation Partner

Whether you choose the DIY route or want full professional support, Tactik Lighting offers:

- Nationwide representation to assist you with your needs

- Network of Electrical Distributors

- Guidance on using the right tools (lux meters, temperature loggers)

- Templates for recording lighting and thermal data

- Expert review of your findings

- Full-service lighting design and implementation

You can start small — or let us handle the heavy lifting from start to finish.

Why Choose Tactik Lighting?

4 Week Lead Times

On All Orders

Custom Configurations

We Welcome Challenges

Made In The USA

Thousands of SKUs Made Here

* Lead times are subject to product availability.